Why is the cardan shaft between the motor and the rotor of a Wangen progressive cavity pump so much more reliable than ball joints?

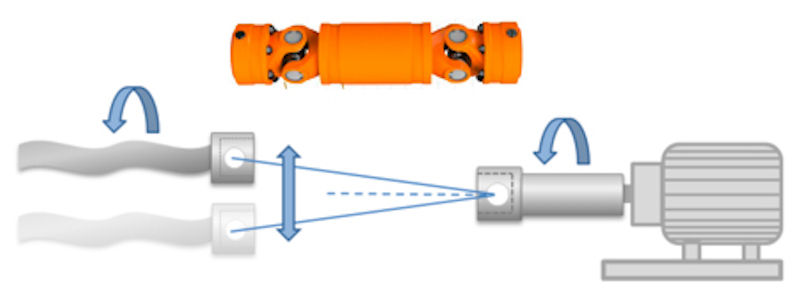

In a progressive cavity pump (PC Pumps), the rotor must not only turn on itself, but must also oscillate vertically in the stator opening.

Consequently, the motor must transmit the rotational movement off its axis.

Competing progressive cavity pumps, such as Seepex®, Allweiler®, Netzsch®, Mono Pumps® or Robbins Meyer®, and many other brands use two ball joints (Pin Joint).

However, these are very fragile, at least compared to cardan drives.

The entire power transmission is concentrated in one point.

As a result, over time, the ball joint and the oscillating pin become deformed. The deformations cause vibrations, so much so that the rotor sometimes has to be replaced just because the ball joint on the drive shaft is out of round.

To avoid this problem, Wangen Pumps use a cardan shaft transmission, similar to the cardan shafts seen in truck transmissions.

It is extremely robust, with no vibrations or premature wear.

Other benefits

The cardan shaft has a more regular diameter than ball joints.

This has the effect of reducing turbulence and reducing the number of “dead” zones, which are always more complicated to clean.

Wangen HILINE pumps for food applications have a perfectly constant diameter drive shaft.

You already use Progressive Cavity Pumps of other Brands

SPS offers a comprehensive range of spare parts for progressive cavity pumps such as Allweiler ®, Bornemann ®, Seepex ®, Netzsch ®, Mono Pumps ®, Wangen Pumps ® and many others.

Call us on +32 2 657 23 53 or email us at info@sps-pumps.com for immediate assistance.