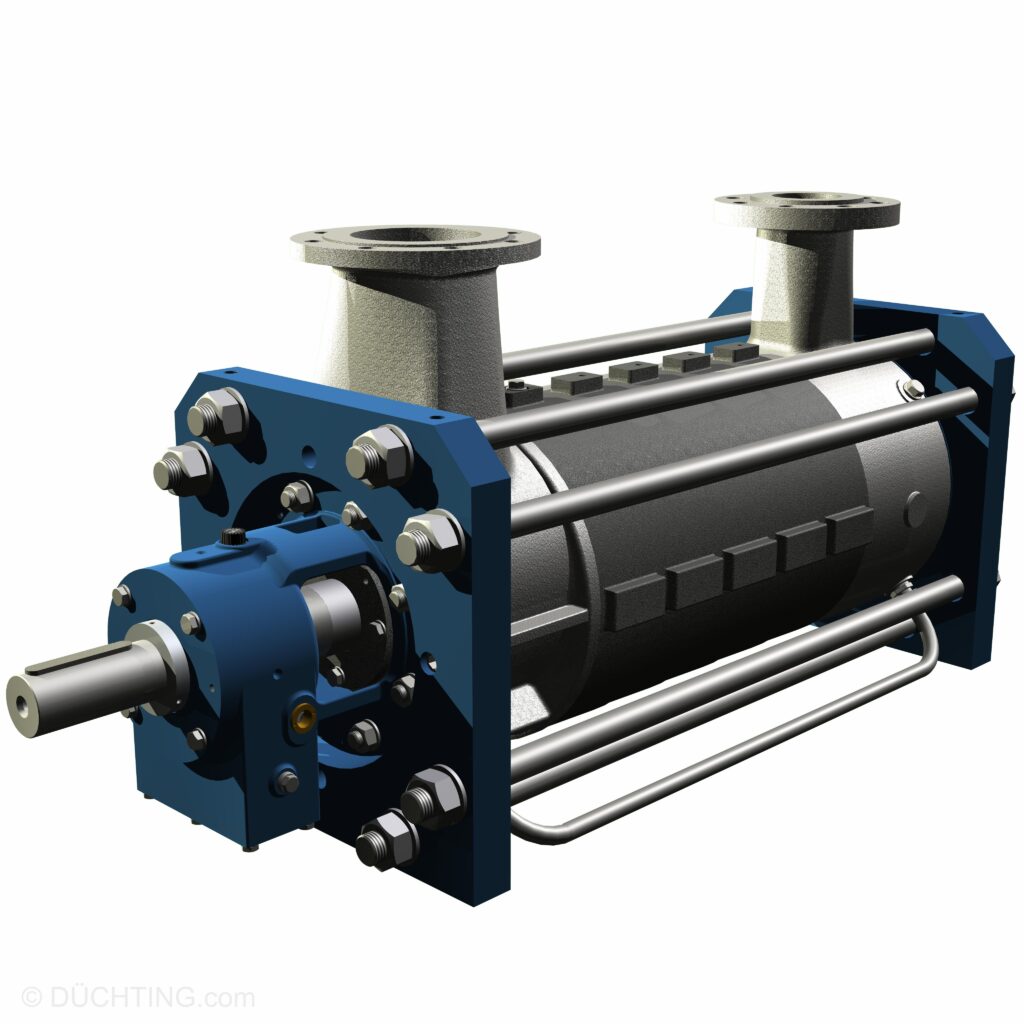

Düchting HPH Pump

High-Performance Multi-Stage Pumping for Demanding Applications

The Düchting HPH pump is a multi-stage centrifugal pump engineered for high-pressure applications in diverse industrial settings.

This ring-section design pump offers exceptional performance, reliability, and versatility in handling clean or slightly polluted liquids, whether chemically neutral or aggressive.

Versatile Configurations and Optimised Hydraulics

The HPH pump provides flexible configuration options, with axial or radial inlets and radial discharge flanges positioned at 90° increments. This allows for easy integration into various piping systems. Replaceable rings in composite material maintain optimal efficiency and reliability, even after extended operation.

To ensure smooth operation and long service life, the HPH pump utilizes axial thrust compensation through balancing discs, a balancing drum, or a combination of both. This minimises axial forces on the rotor, reducing wear and tear on bearings and other components.

Customisation Options for Specific Needs

Düchting offers tailor-made HPH pump solutions to meet specific customer requirements.

Pump dimensions can be adapted, and impellers can be fixed with keys for applications like back-flushing.

Impeller wear rings are also available for enhanced durability.

The pump can be configured with one or two connective shaft ends for added flexibility in installation and operation.

To achieve outstanding hydraulic performance, impellers and diffusers are cast using ceramic molds, resulting in smooth surfaces that minimize friction losses and maximise efficiency.

Material Selection for Demanding Environments

It offers large versatility in material selection, with options ranging from cast iron to SUPER DUPLEX stainless steel with Pitting Resistance Equivalent numbers (PREN) above 40, ensuring long-term reliability in aggressive environments.

We carefully selects materials for the HPH pump based on the specific application and operating conditions.

Compliance

Compliance

The HPH pump is manufactured according to DIN/ASME standards, and upon request, API 610 and ATEX approved for use in potentially explosive atmospheres.

Key Advantages

- High-pressure, multi-stage design for demanding applications.

- Versatile configurations for flexible installation.

- Optimised hydraulics for exceptional performance.

- wear parts for easy maintenance.Tailor-made solutions to meet specific needs.

- Wide range of materials for diverse applications.

- Manufactured according to ISO, DIN, and ASME standards (API 610 upon request).

Applications

- Pressure boosting systems in industrial processes

- Water supply and water treatment

- Seawater desalination

- Condensate production

- Boiler feed systems

- Hot water applications

- Petrochemical applications

- Water injection

Technical Data

| Pump size | DN 80 to DN 300 | |

| Maximum Pressure | 100 bar | |

| Maximum Flow | 3 500 m3/h | |

| Total Head | up to 1100 m | |

| Rotating Speed | up to 3600 rpm |

SPS Pumps is There to Help

At SPS Pumps, our Düchting Centre of Excellence is there for you, to help finding the most adequate pump for your application. Our expertise is second to none.

This information is provided with the permission and courtesy of Düchting Pumpen GmbH.